Supply of High-quality Coal Preparation Plant Equipment and Spare Parts

Alpha Ind. Tech.

Discover our top-quality range of coal preparation plant equipment and spare parts, tailored to meet the demanding needs of the industry. Our collection includes advanced X-ray transmission (XRT)ore sorters, innovative centrifuges, teetered bed coarse slime separator, precise screening systems, robust pumps, reliable valves and efficient separators. Each product is meticulously designed to enhance the performance, efficiency, and reliability of your coal preparation operations.

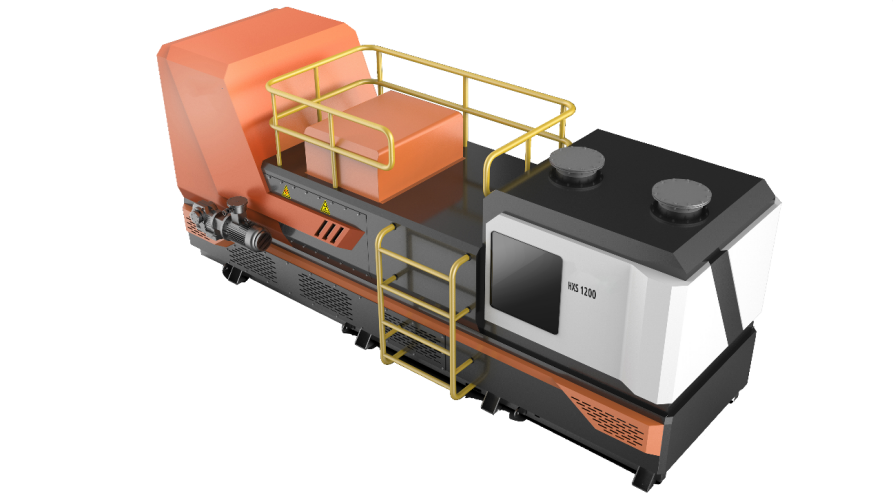

XRT Intelligent Sensor-based Ore Sorter (Water-free Processing)

XRT SORTER is an efficient intelligent ore pre-concentration equipment (water-free process) that combines X-ray transmission(XRT), image recognition and AI algorithm technology.

It is widely used in the separation of metal/nonmetallic ores, industrial ores, energy (coal preparation) minerals, slag, diamond, etc.

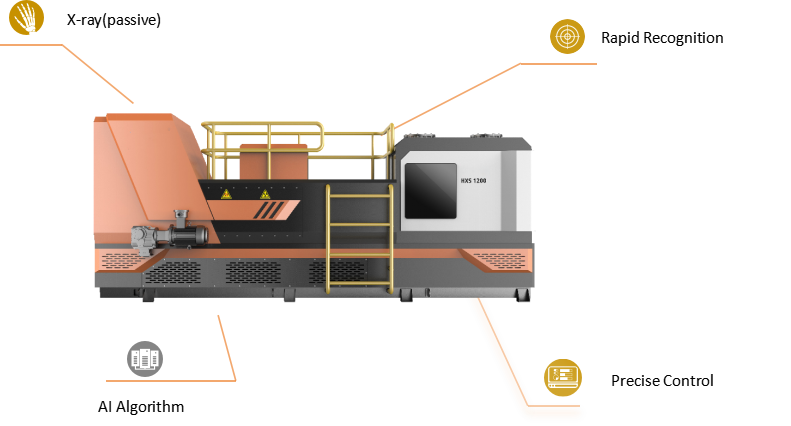

Intelligent Coarse Coal Centrifuge

The intelligent centrifuge (horizontal vibrating) can realize efficient dewatering of coal slime(+0.5-50mm) by centrifugation and vibration.

Applications:

Fine Coal Clean Coal/Middings

Fine Gravel/Sand Leopoldite

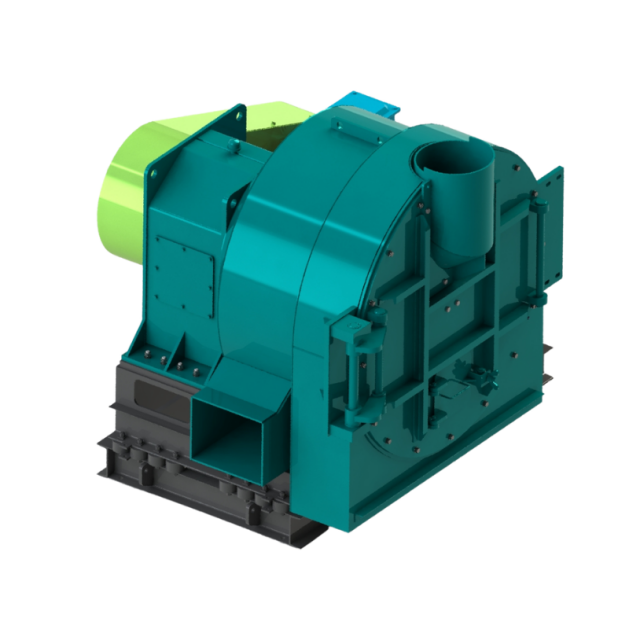

Intelligent Fine Coal Centrifuge

It can be widely used in the rapid, efficient, and stable dewatering process of fine coal.

Advantages:

·Low moisture;

·High separation efficiency;

·Wear resistance design

Horizontal Screen Bowl Decanter Centrifuge

It realizes efficient dewatering of ultra-fine coal slurry by centrifugal sedimentation and centrifugal filtration technology.

◆Full automatization ◆Ultra-fine solid liquid separation ◆ Easy maintenance ◆Durable design

Teeter Bed Coarse Slime Separator

The TBS requires only water as a medium to realize the highly automated treatment of coal slurry.

·Automated operation;

·Backwater self-stabilized system;

·Patent bell discharging valve;

Coal Fines Deep Classification Roller-disc Screen

The coal fines deep classification roller-disc screen can be used for raw coal desliming to reduce the load of slime water and improve the overall treatment capacity of the coal preparation plant.

Advantages: Large capacity; High efficiency; Wide feeding range

Intelligent Filter Press

ALPHA is a leading supplier of comprehensive and high-performance filter press. Automatic feeding, automatic feed end, automatic queue discharge, system safety interlock, and intelligent monitoring of filter press status are the features of our filter presses.

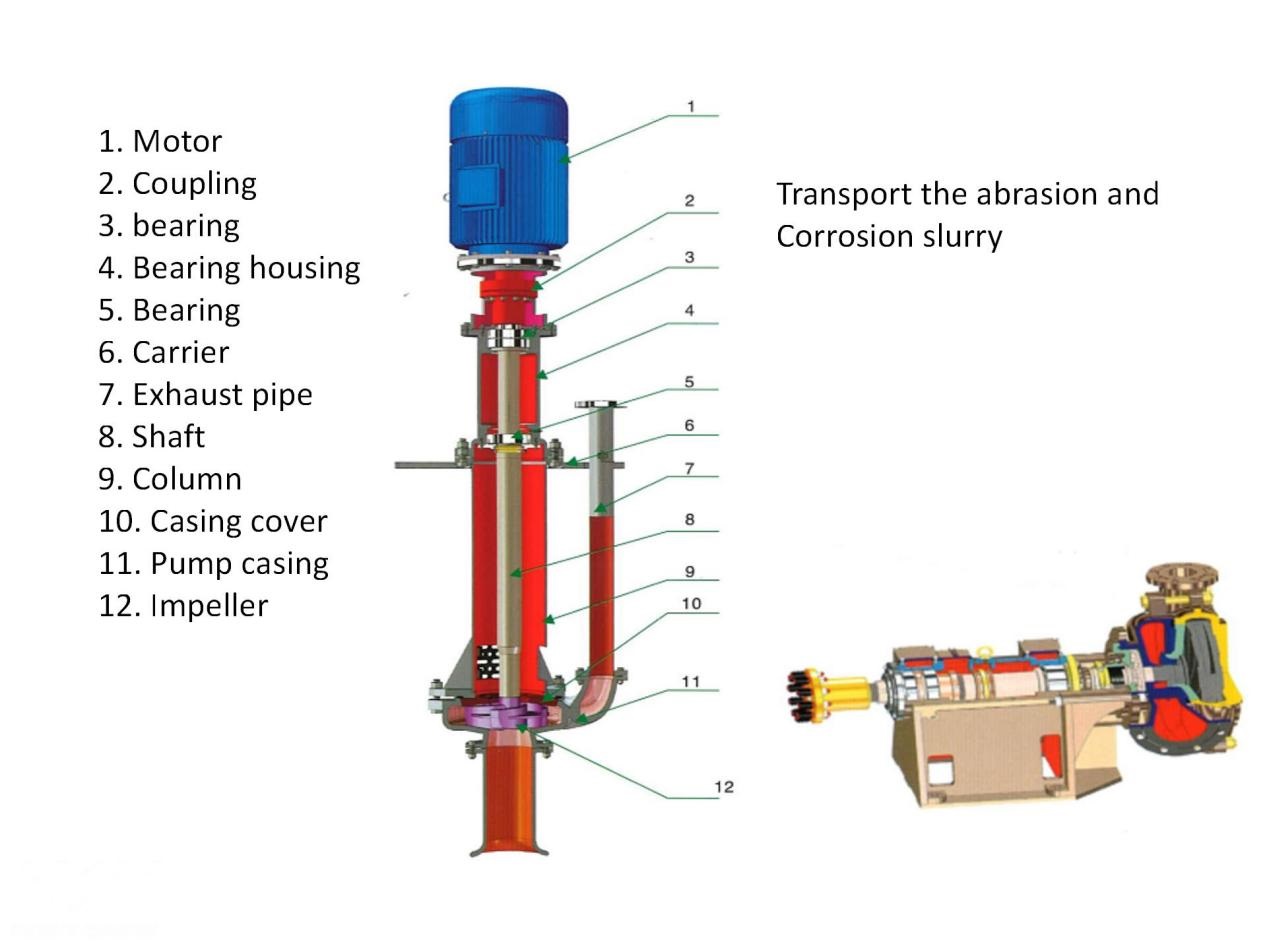

Slurry Pumps

Alpha Slurry Pumps are widely used in electric power, metallurgy, coal and building materials and other industries to transport abrasive or corrosive slurry containing solid particles. The maximum slurry weight concentration of solid-liquid mixtures allowed to be transported: 45% for ash slurry and coal slurry, 60% for ore slurry and heavy duty slurry. Alpha slurry pumps can be operated in series according to the requirements of users.

According to type of structure, the pumps are classified into single-case and double-case pumps. The outlet diameters of pumps vary from 550mm to 500mm, 400mm, 350mm, 300mm, 250mm, 200mm, 150mm, 100mm, 80mm, 65mm, 50mm, 40mm, 25mm,etc.

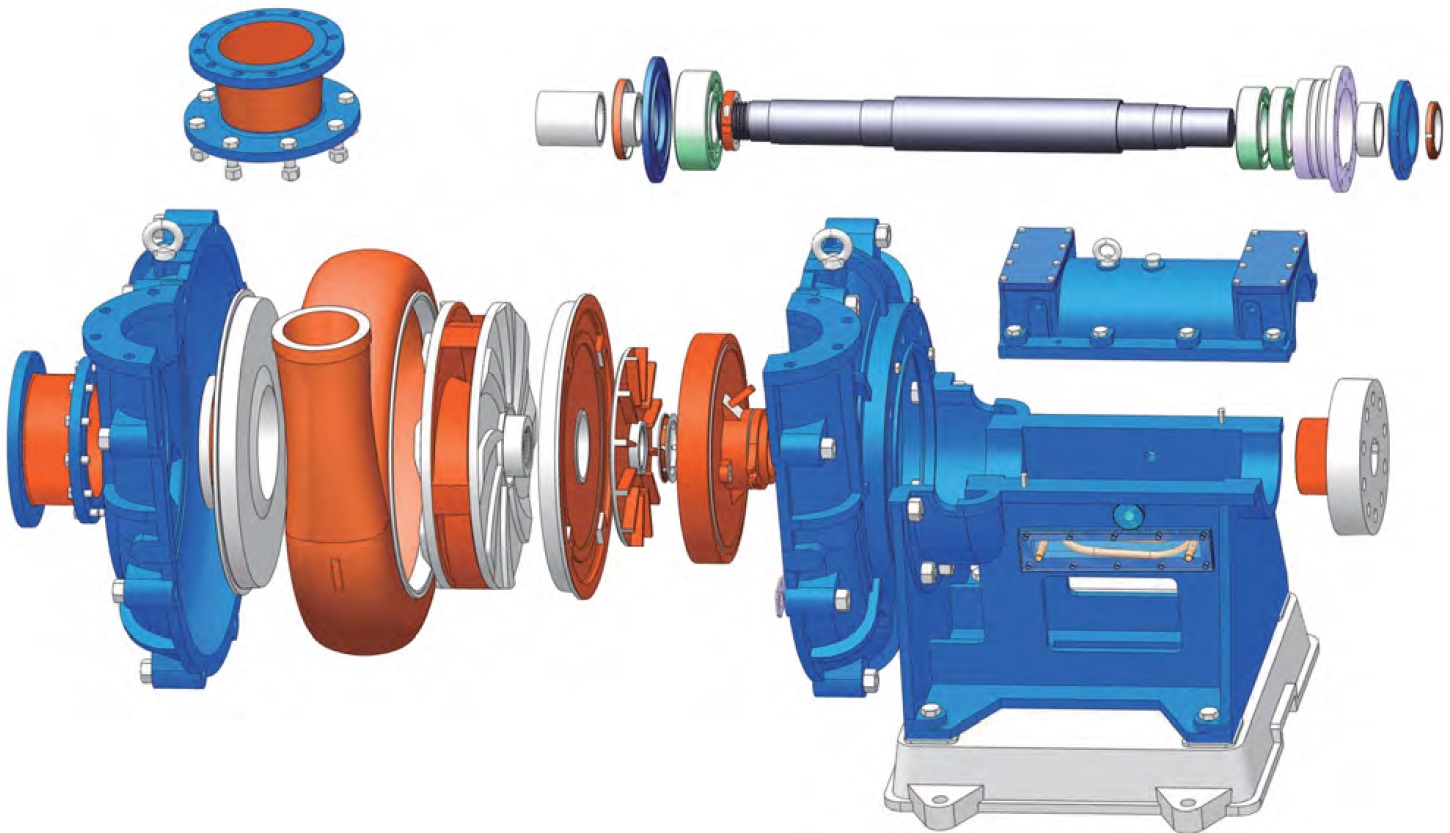

Structure Features

Structure Features of Pump Head:

· Apply of double-case pumps or single-case pumps according to requirement.

· Double-case pumps centrally split in vertical direction. Discharge port can be positioned at 8 different position at an interval of 45°.

Support:

· Centrally split in horizontal direction

· Hanger bracket

Shaft Seal:

· Expeller Seal and Packing seal

· Packing Seal

· Mechanical Seal

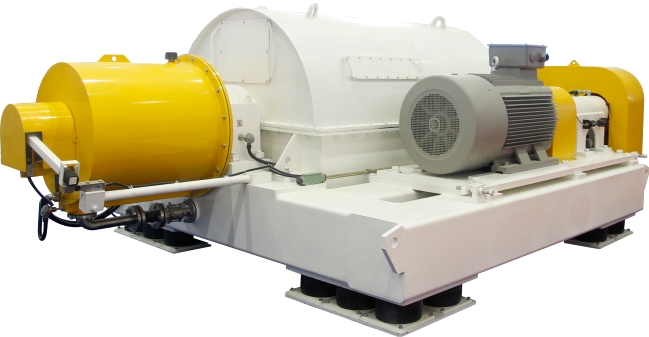

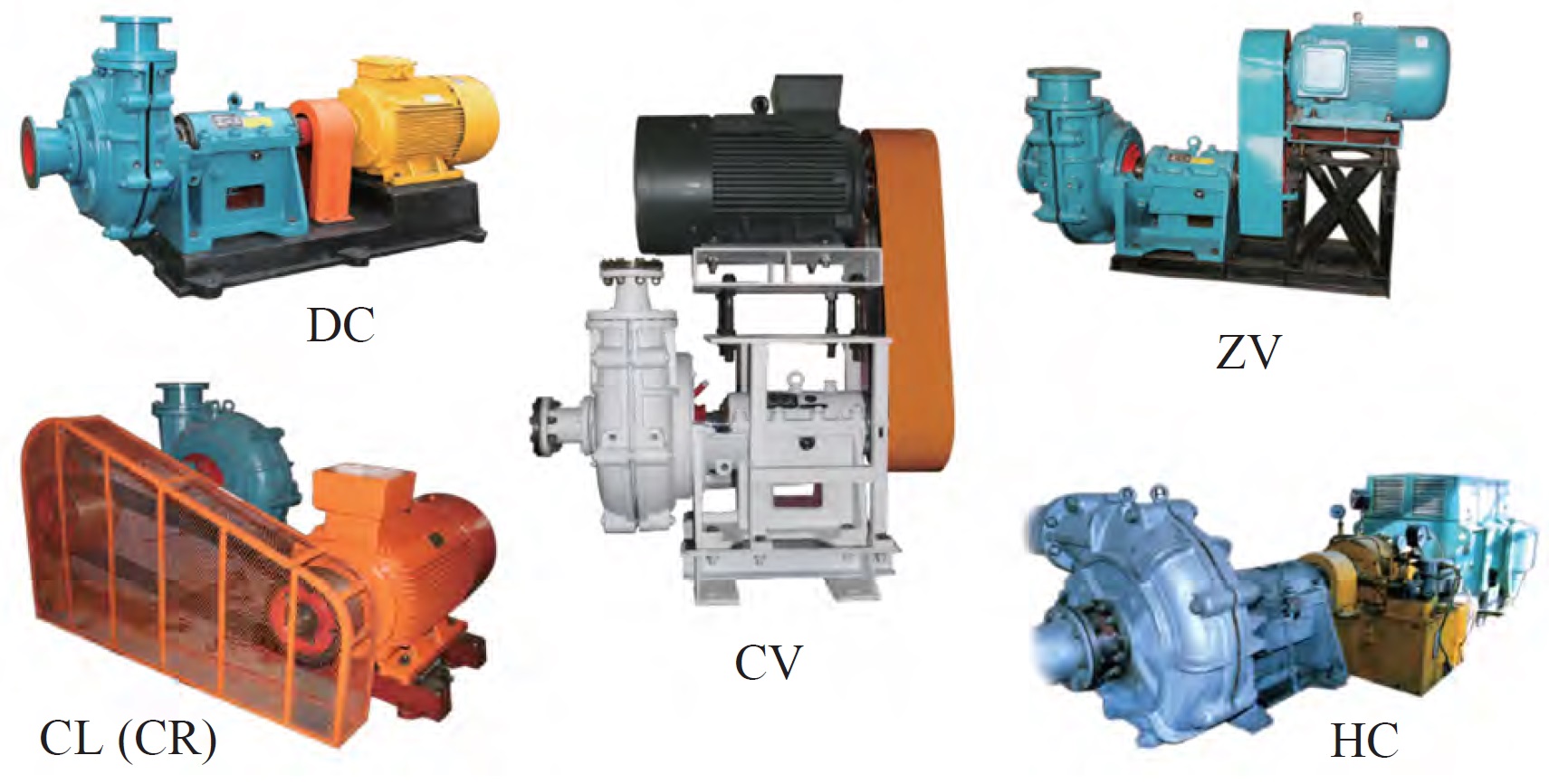

ALPHA's slurry pumps can be categorized into three main types based on their driving modes:

1. Direct Driven (DC)

2. Direct Driven via Hydraulic Coupling (HC)

3. Belt Driven (CR, CL, ZV, CV)

Features of Material:

·Metal

·Anti-abrasion metal materials

·Anti-abrasion and anti-corrosion metal materials

·Anti-corrosion metal materials

Features of Use :

·High efficiency

·Long service life

·Steady operation

Pump Parts

·Primarily servicing spare parts for mainstream and top-tier pump brands;

·In addition to original equipment parts, Alpha also offers a variety of alternative spare parts, rubber liners, rubber impellers, and more.

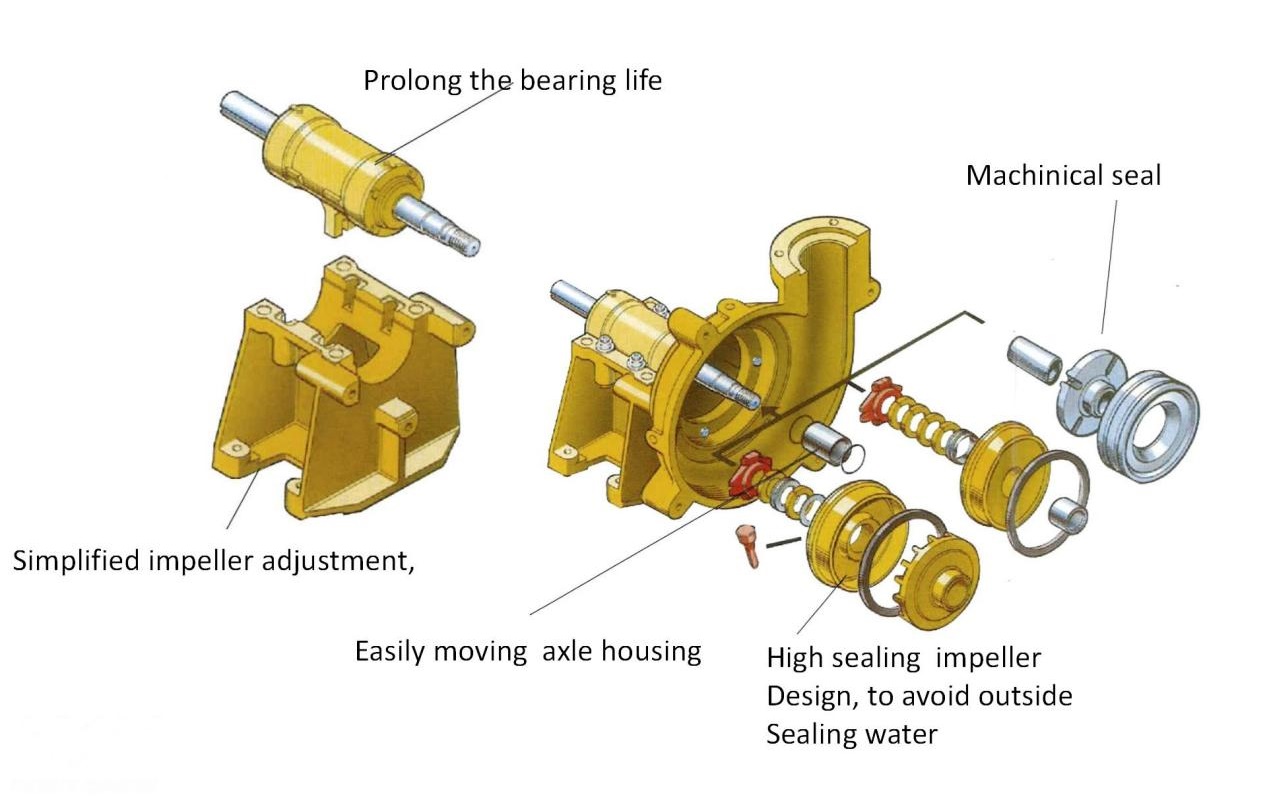

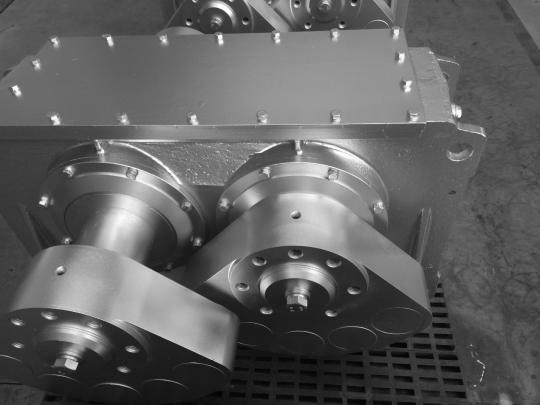

Shaft Basic Bearing Assembling

Advantages

·The optimized life time, the lowest operation cost.

·Adjust bearing components can change the position of the impeller in the pump cavity, keep high effective operation station.

· With detachable type structure, simple structure, easy maintenance, avoid to remove the in and out water piping.

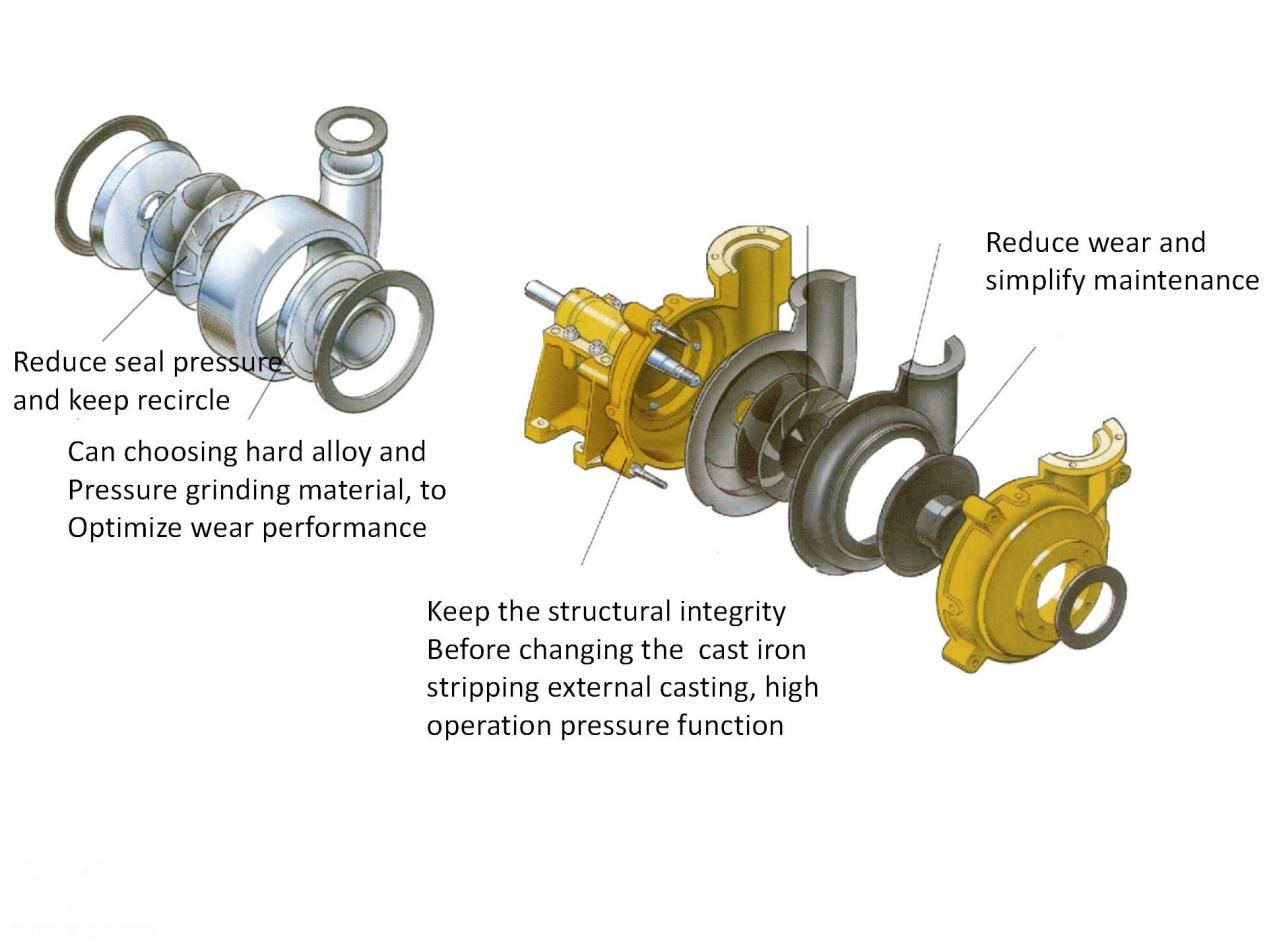

Kinds of Impeller

Intelligent Vibration Exciters ALPHA®

Alpha’s self-developed intelligent vibration exciter is widely used in all kinds of screen equipment, and it can be a perfect substitute for well-known brands' vibration exciter in the market.

Flow Control Valves

All kinds of vales of ALPHA ® can be widely used in coal preparation plants, mineral processing plants, and other water treatment plants.

Contact us for more details:

Sabrina

Mobile: +86 13548060872

Email: sabrina@alpha-technology.com.au

Tiffany Chen

Mobile: +86 18282103350

E-mail: tiffany.chen@alpha1888.com