Distributed Temperature Monitoring System for Mining

ALPHA

1 System Introduction

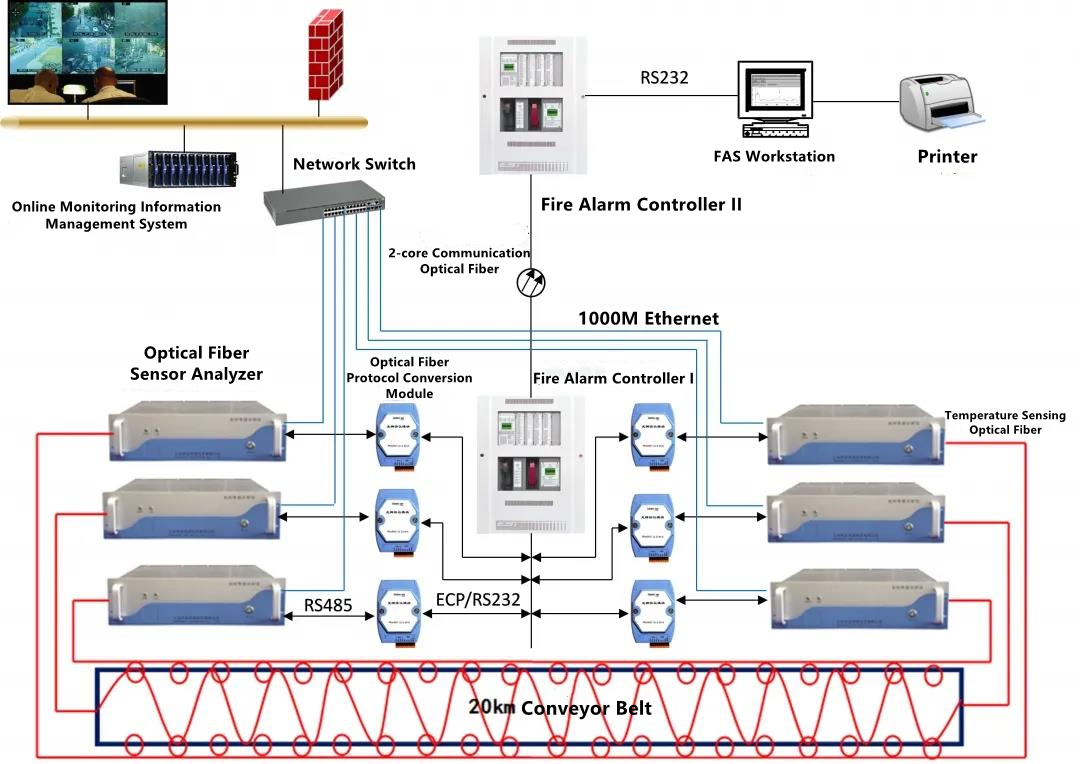

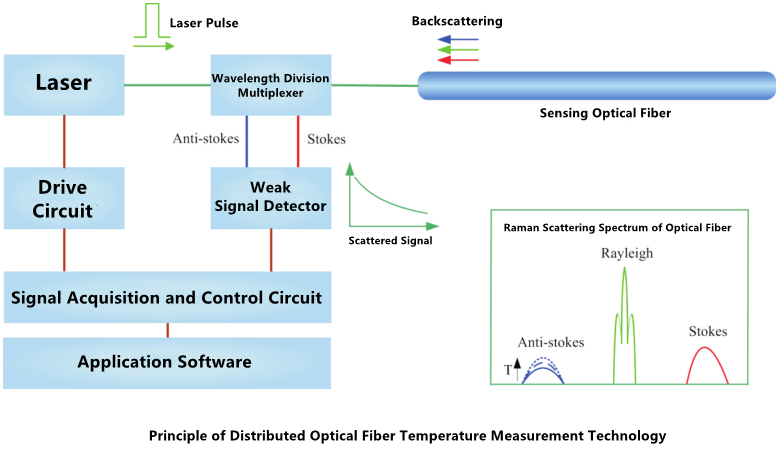

The distributed optical fiber temperature measurement system is composed of distributed optical fiber thermometer, temperature sensing optical cable, measurement software and other ancillary equipment. The system uses the principle of Raman scattering and optical time domain reflection (OTDR) to obtain the spatial temperature distribution information. When the laser pulse with a certain energy and width is transmitted in the measuring fiber, the backscattered light is produced, and its intensity is affected by the temperature of the scattering point of the fiber. After wavelength division multiplexing and detection, the scattered optical signal enters the signal processing system to extract the temperature information of each position on the measuring optical fiber in real time. At the same time, the position of the measured temperature is located by using the propagation speed of the optical wave in the optical fiber and the time interval of the backscattered signal. The system has the advantages of distributed measurement, anti electromagnetic interference, anti-corrosion, long measurement distance and low maintenance cost, which is widely used in coal mine and non coal mine temperature monitoring and security.

2 Application Scenarios

Belt transportation parts, power distribution transmission parts, cable bridge parts, coal yard, etc

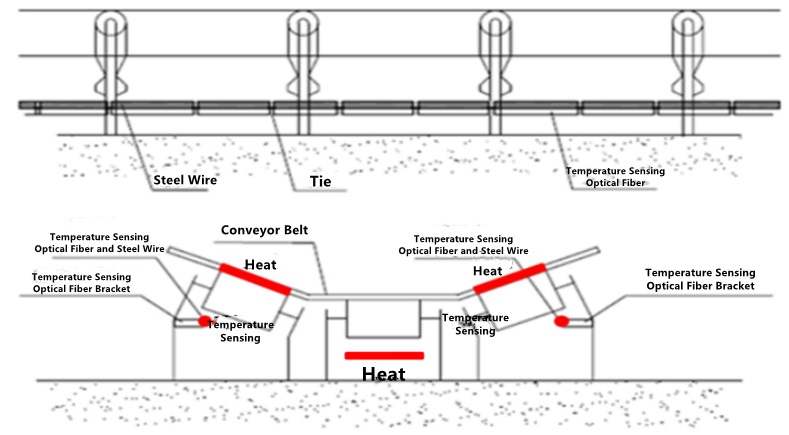

Optical cable laying mode of belt conveyor:

Along the belt direction, both sides are laid in a straight line; the key parts (bridge stack, head and tail) are monitored by the constant temperature disk (the length of optical cable is 10m).

Flammable point:

1. Bottom of belt; 2. Head and tail of belt conveyor; 3. Roller; 4. Motor (temperature sensing cable can cover)

Laying method of distribution transmission part:

It mainly adopts point laying, and the temperature sensor of thermal conductive ceramic is installed in the power distribution transmission part.

Cable tray laying method:

When applied directly, the length is 1.2 times of the monitoring object, and when applied in S type, the length is 1.5 times. 1 meter apart. If the bridge width is more than 1m, optical cables shall be laid on both sides.

Contact ALPHA For Your Mine Projects

Web: http://www.alpha-technology.com.au/

Liv

Email: liv.wang@hot-mining.com

Tel: +86 18227011092