Do you really know different level of Underground Mining Equipment Remote Control?

ALPHA

ALPHA is professional at underground mining equipment remote control, and also provide different level of remote control system to customer according the specific requirements. So, Alpha would like to tell you different level remote control system has different functions.

From line of sight remote control to autonomous control, roughly divided into 4 levels, as follows

Line Of Sight Remote Control (Video)

The operator uses the video remote control to operate the vehicle in the safe area,and they can operate at corners and out of sight. The vehicle can only be operated by one person through remote control transmitter. This has been able to initially keep drivers away from the core dangerous areas, to a certain extent, the safety of operators is guaranteed. But because drivers have to look at the monitor and operate frequently, sometimes they are prone to fatigue and operation errors, so drivers still have safety risks. The remote-control vehicle runs at the first gear speed, which may be due to the dark light in the underground, the bucket is not visible and the bucket is not full, so the production efficiency is generally lower than the manual control. The remote control distance is generally 100~500 meters.

Line Of Sight Remote Control Operating Site

Line Of Sight Remote Control Operating Site

Preliminary Tele Remote Control

The underground mining vehicles are integrated into the mine network, and remote control can be achieved in the areas covered by the network. Operators can fix or move operation stations in mines or control mining equipment in ground centralized operation centers. In production, the underground mining vehicles are operated by manual remote control, without the function of automation. Generally speaking, mining vehicles can run in two gears (mainly to avoid collision with roadways). Production efficiency is a little lower than manual control.

Tele Remote Control Operating Site

Tele Remote Control Operating Site

Semi-autonomous Tele Remote Control

1 operator can operate 3 mining vehicles simultaneously in underground or ground control centers. Mining equipment transportation, unloading automation, manual remote control of loading. High productivity, mining vehicles can drive in 2nd gear (mainly to avoid collision with the gallery), the vehicle waiting time is short, the production time is long.

Semi-autonomous Tele Remote Control

Autonomous Tele Remote Control

1 operator can operate 3 to 6 mining vehicles simultaneously in underground or ground control centers. The whole process does not require human intervention, the vehicle basically depends on autonomous operation. The operator only needs to "supervise" the operation of the vehicle.

At present, only a few internationally renowned mining equipment companies have commercialized the technology. Including: Epiroc, Sandvik. etc.

It's worth mentioning that Alpha's intelligent load-haul-dump (LHD) is about to launch, which will be China's first autonomous LHD. More than this, intelligent LHD also uploads the operation parameters of LHD to Alpha cloud for intelligent predictive maintenance through built-in sensing technology to ensure efficient and long-term operation.

Autonomous Tele Remote Control

Autonomous Tele Remote Control + Predictive Maintenance System

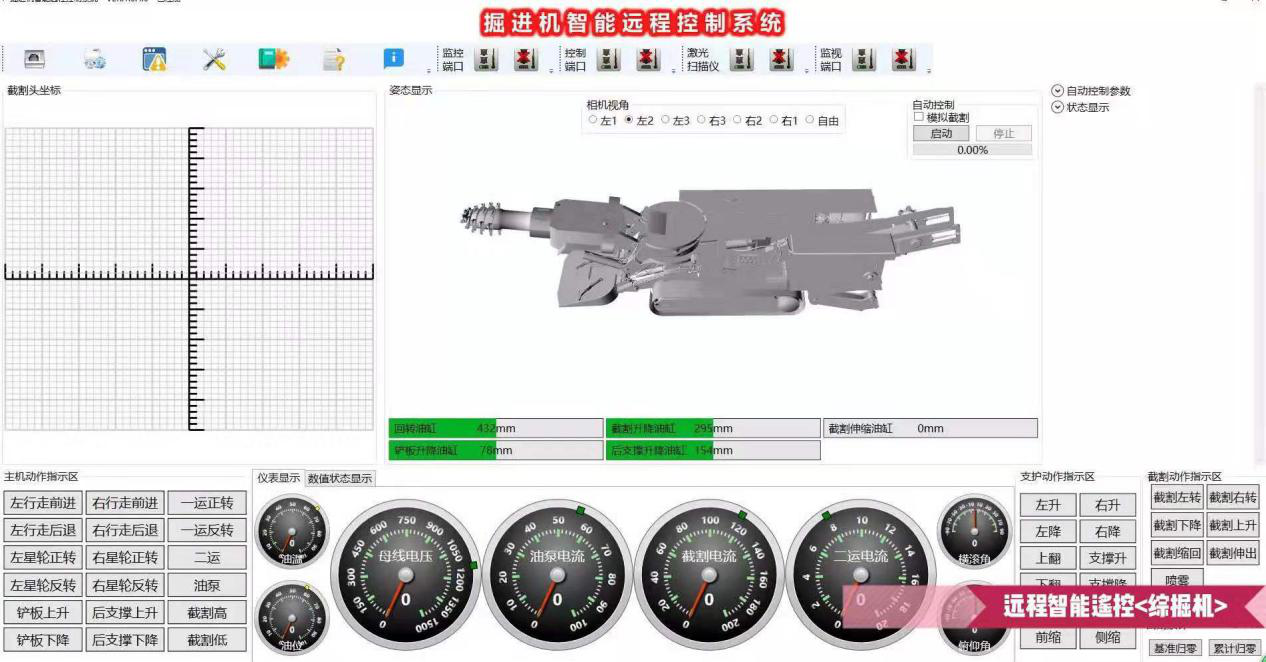

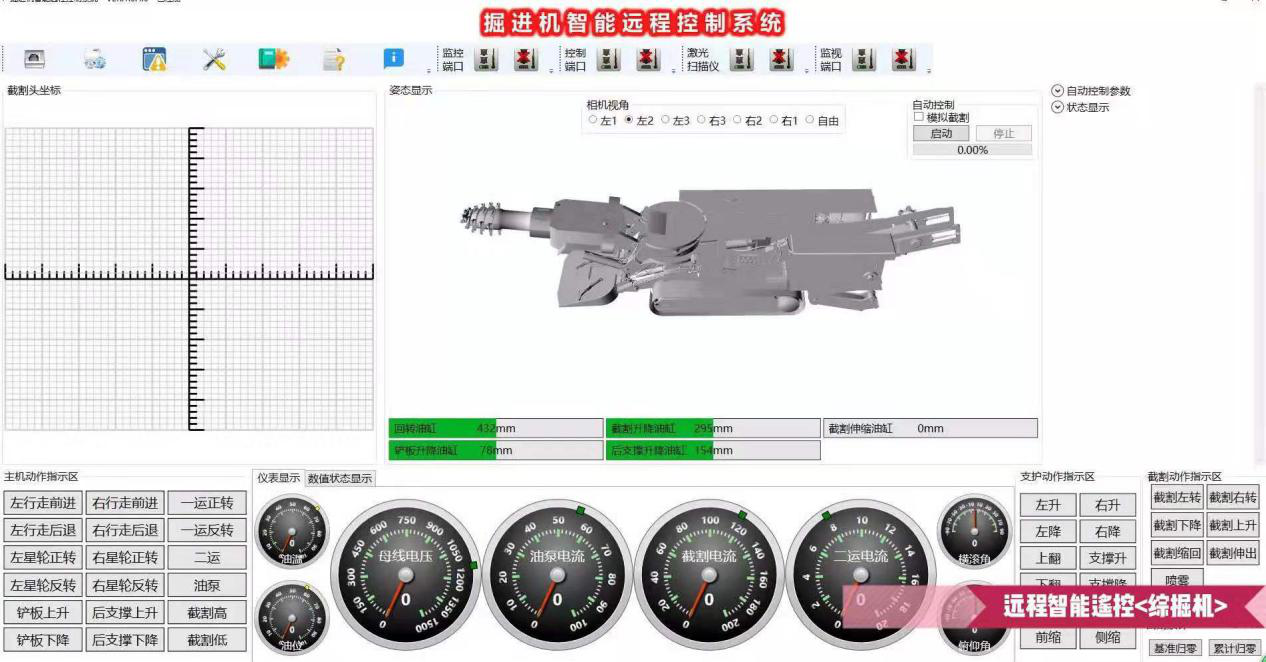

ALPHA proves the intelligent operation of remote operation by example, which has been used in the complex underground coal mining. In view of the over-sight distance remote control of coal mine roadheader, but because the coal mine roadheader is different from the LHD such flexible trackless equipment, the second level of over-sight distance remote control has been able to meet the requirements of underground coal mining.

Over-the-horizon Remote 0peration

Interface Of System Control

Wanna know more about the ALPHA Remote Control System, just contact us for details:

E-mail: kyle.lee@alpha-technology.com.au

Tel/WhatsApp(Skype): +86 15756875803

Web: http://www.alpha-technology.com.au/Products/type/18