The Revaluation of Online Screen Monitoring Solution by Data-Driven and AI

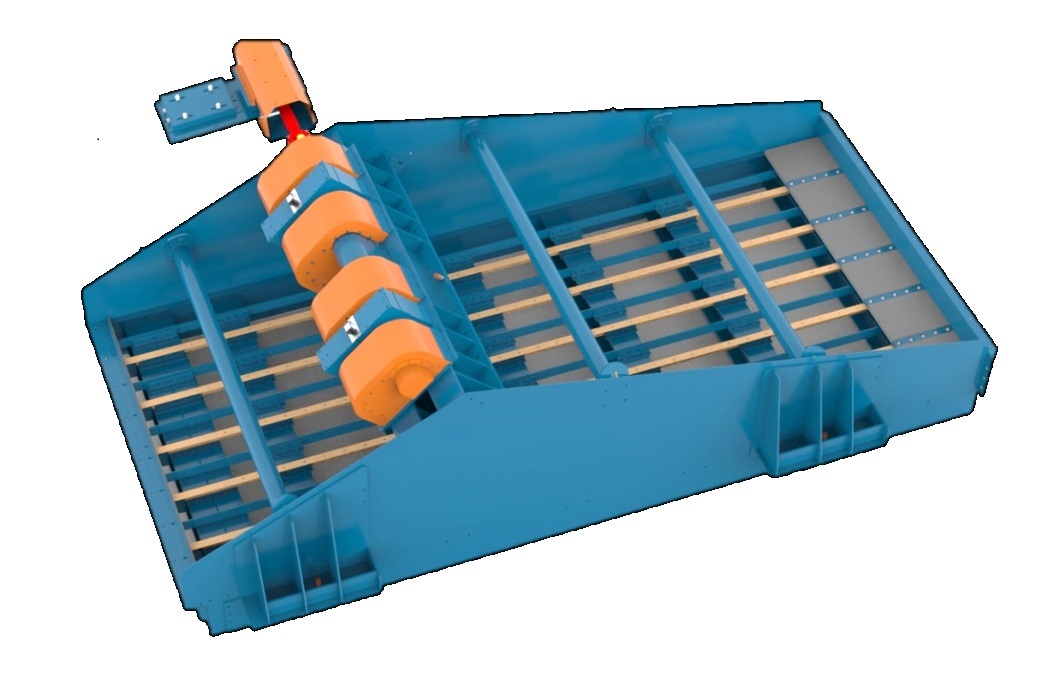

A vibrating screen is a large, heavy piece of equipment widely used in the mining industry and it is usually arranged in the throat of the production process system. Unfortunately, the difficulty of daily maintenance and upkeep of vibrating screens leads to frequent equipment failures, which can cause loss of profits ranges from tens of thousands to millions of yuan. Most importantly, premature failures of vibrating screens during operation will directly threaten the safety of inspection personnel's lives. The PHM maintenance system for vibrating screens developed by Alpha Intelligence uses sensor technology, automatic control technology, Internet of Things technology, and big data technology to monitor various operating parameters of vibrating screens in real-time online.

Key functions of the PHM system include:

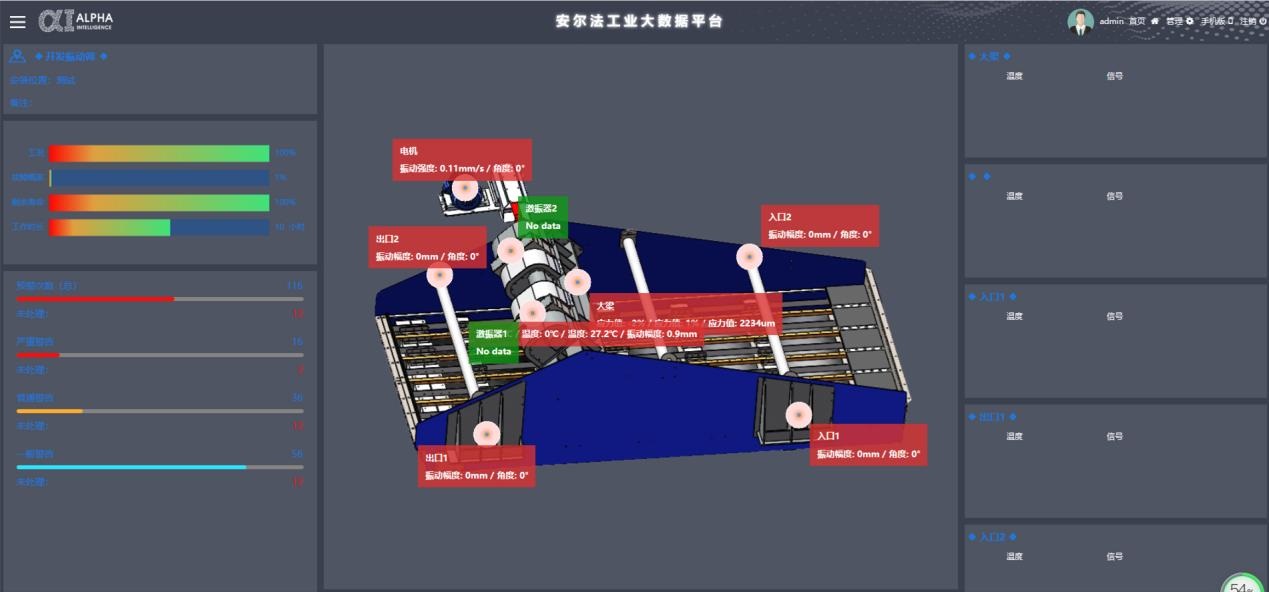

1) Monitoring function: continuous status monitoring and browsing historical data.

2) Alarm function: automatic warning, automatic alarm, WeChat push alarm information.

3) Analysis function: equipment condition prediction, maintenance plan push.

4) Auxiliary function: equipment QR code management.

5) Push function: AI algorithm analysis and report generation push to WeChat client.

6) Monitoring parameters: motor vibration temperature, screen body vibration intensity, screen body vibration angle, screen body vibration balance, exciter operating bearing temperature, lubricant temperature, etc.

Real-time online monitoring

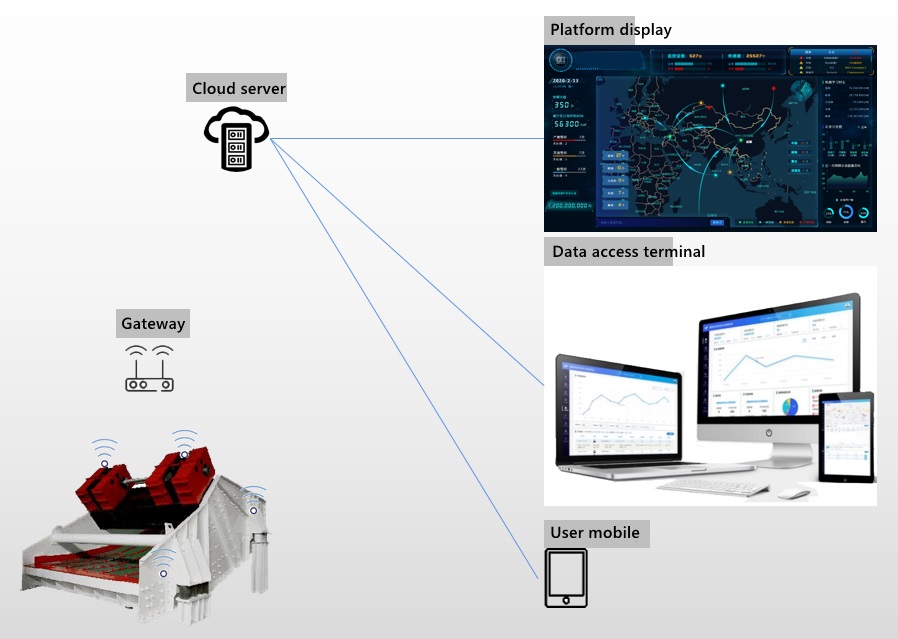

Real-time online monitoring is conducted on the core components of the vibrating screen, primarily focusing on monitoring the motor vibration temperature, vibration balance of the feed inlet before and after the screen, vibrator vibration, four bearing temperatures, and lubricating oil temperature. To ensure accessible data collection and reduce implementation difficulty, on-site sensors are battery-powered and utilize wireless data transmission. The sensors monitor and collect vibration and temperature data for a particular duration at set intervals and wirelessly transmit the data. A relay is deployed near the vibrating screen to receive data from multiple sensors and send the data to the enterprise cloud platform for data analysis via the on-site or 4G/5G network. Real-time online monitoring can effectively monitor the vibration balance of the screen during equipment operation, uneven feeding, and vibrator bearing faults, allowing timely detection of equipment failures and corresponding measures to avoid accidents.

Continuous state monitoring

Alpha' PHM system utilizes multi-channel state monitoring technology designed explicitly for the vibrator in the vibrating screen. It is cross-connected with the vibrator in the vibrating screen to detect and evaluate phase defects, examine and record bearing and gear vibration, operating oil temperature, and overall machine motion in six degrees of freedom (three translations and three rotations).

Main features: 1) Machine condition visualization. 2) Detailed view of the selected machine status. 3) Real-time push of dashboard data. 4) Responsive web design - dashboard panels adapt to screen resolution and panel interaction. 5) Time zone and language automatically adapt to the client system. 6) Alert push within the threshold limit range.

Cloud platform & cloud services

The cloud platform employs big data, artificial intelligence technology, and other technologies to establish equipment models and algorithms, continuously training and learning to improve the reliability and accuracy of equipment failure warnings. By introducing the model with long-term monitoring data and using real-time data as input, the trend of various monitoring indicators can be predicted and analyzed to determine equipment performance status and predict equipment failures. Fault information is promptly pushed to the relevant personnel through the APP or WeChat public account for timely measures, eliminating faults in the bud.

Sensor info:

Model:AD006

Waterproof level:IP66

Acceleration measurement range:±16g

Frequency range:1000Hz

Measurement axes:3

Sensitivity:51mV/g

Singal type:Zigbee

Transmission rate:250Kbps

Working frequency:2.405GHz~2.485Ghz default 2.48Ghz

Wireless transmit power:8dBm

Wireless communication distance: line-of-sight transmission distance 500 meters @5dbi antenna

Vibrating Screen PHM Application - Shaanxi Balasu Coal Preparation Plant

Conclusion

Alpha Industries' PHM maintenance system is committed to the smooth operation and intelligent operation of vibration screens, from initial real-time monitoring to industry expert support for historical equipment issues. Customers can access real-time dashboards with KPI information on mobile devices and get all relevant information anytime, anywhere.

Global overall settings and systematic layout optimization enable customers to obtain data interpretation, maintenance suggestions, and maintenance methods on the client side, supplemented by considerable historical data support at various levels, assisting the factory's workforce.

Future research directions: Alpha Industries is developing a new type of vibration screen PHM system that can monitor the movement, status, and performance of vibration equipment and the rate of unbalanced vibrators driving vibration screens and feeders. With minimal installation work, a wireless sensor can be installed on the cover of the vibrator using a magnet. Once the vibrator is fatigued, the sensor picks up high-frequency signals from worn bearings and gears.

X

Welcome to alpha !