Wireless IoT Sensors

Chengdu Alpha Industrial Intelligence Co., Ltd., a national high-tech enterprise, focuses on providing intelligent solutions based on the Internet of Things.

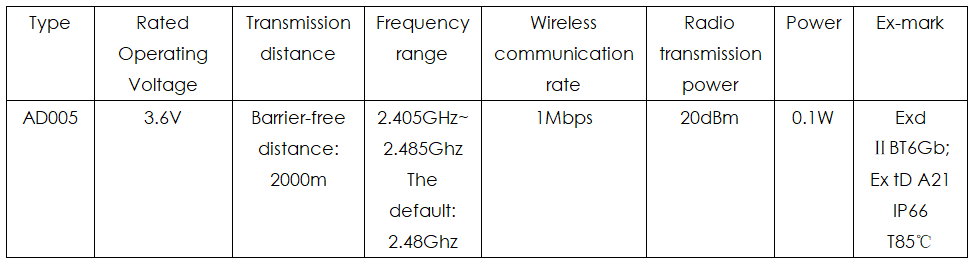

1.AD005 Wireless Accelerator & Temperature Sensor

1.1 Basic Parameters

1.2 Application

AD005 intelligent monitor terminal (hereinafter referred to as the Accelerator&Temperature Sensor) apply to explosive gas environment (area 1 and area 2) , combustible dust environment (21 and 22 area) and explosive air-mixture places of levels AⅡ,BⅡ,CⅡor of temperature classes ranging from T1 to T6. The power required for collecting and transmitting Accelerator and temperature signal in workplace is supplied by 3.6V lithium battery.

a)Applicable working environment temperature: -40℃ ~ +85℃

b)Relative applicable humidity:≤95%(20℃)

c)Temperature measurement range: -55~+125℃

d)Accelerator measurement range: 1000Hz,±16g

e)Pollution degree rating: 3

f)Risk class for explosive new gas mixtures: ⅡA,ⅡB,ⅡC

g)Applicable for the environment of non-destructive insulation of gas or steam

1.3 Structure Overview

Accelerator&Temperature Sensor is composed of waterproof housing, circuit board, Accelerator sensor, temperature sensor and antenna. The shell is made of aluminum alloy die-casting. After high-speed shot blasting, the surface is sprayed with high-voltage electrostatic plastic, which is strong anticorrosive and can be used in all kinds of harsh environments. All external ports are waterproofed to ensure that the equipment operates in an airtight environment. It has High protection structure and optimized maintenance operation.

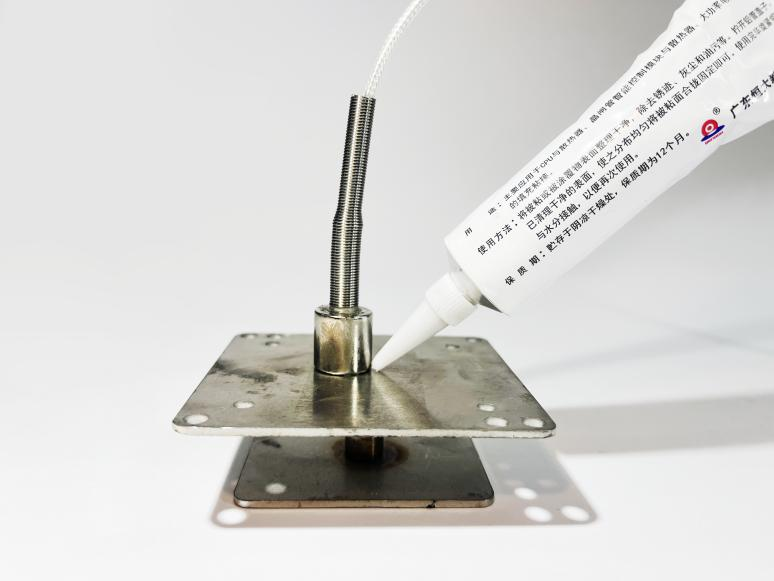

The Accelerator&Temperature Sensor shall be installed by bracket with 90-degree i-type or 45-degree inclination. The bottom end of the bracket shall be glued to the monitoring equipment with metal structure adhesive. The top end shall be connected to the bottom of the Accelerator&Temperature Sensor with M3 stainless steel bolts. The temperature sensor is magnetic adsorption probe, which is directly adsorbed on the equipment when used. The antenna is an omnidirectional rotatable antenna.

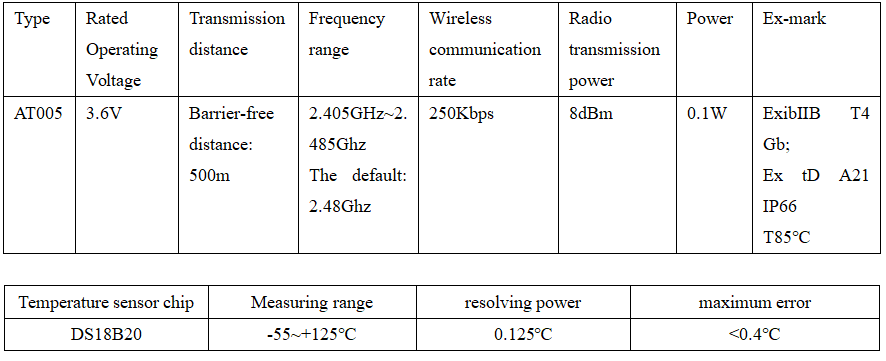

2.AT005 Wireless Temperature Sensor

2.1 Basic Parameters

2.2 Application

AT005 intelligent monitor terminal (hereinafter referred to as the Temperature Sensor) apply to explosive gas environment (area 1 and area 2) , combustible dust environment (21 and 22 area) and explosive air-mixture places of levels AⅡ,BⅡ,CⅡor of temperature classes ranging from T1 to T6. The power required for collecting and transmitting Accelerator and temperature signal in workplace is supplied by 3.6V lithium battery.

a)Applicable working environment temperature: -40℃ ~ +85℃

b)Relative applicable humidity:≤95%(20℃)

c)Temperature measurement range: -55~+125℃

d)Pollution degree rating: 3

e)Risk class for explosive new gas mixtures: ⅡA,ⅡB,ⅡC

f)Applicable for the environment of non-destructive insulation of gas or steam

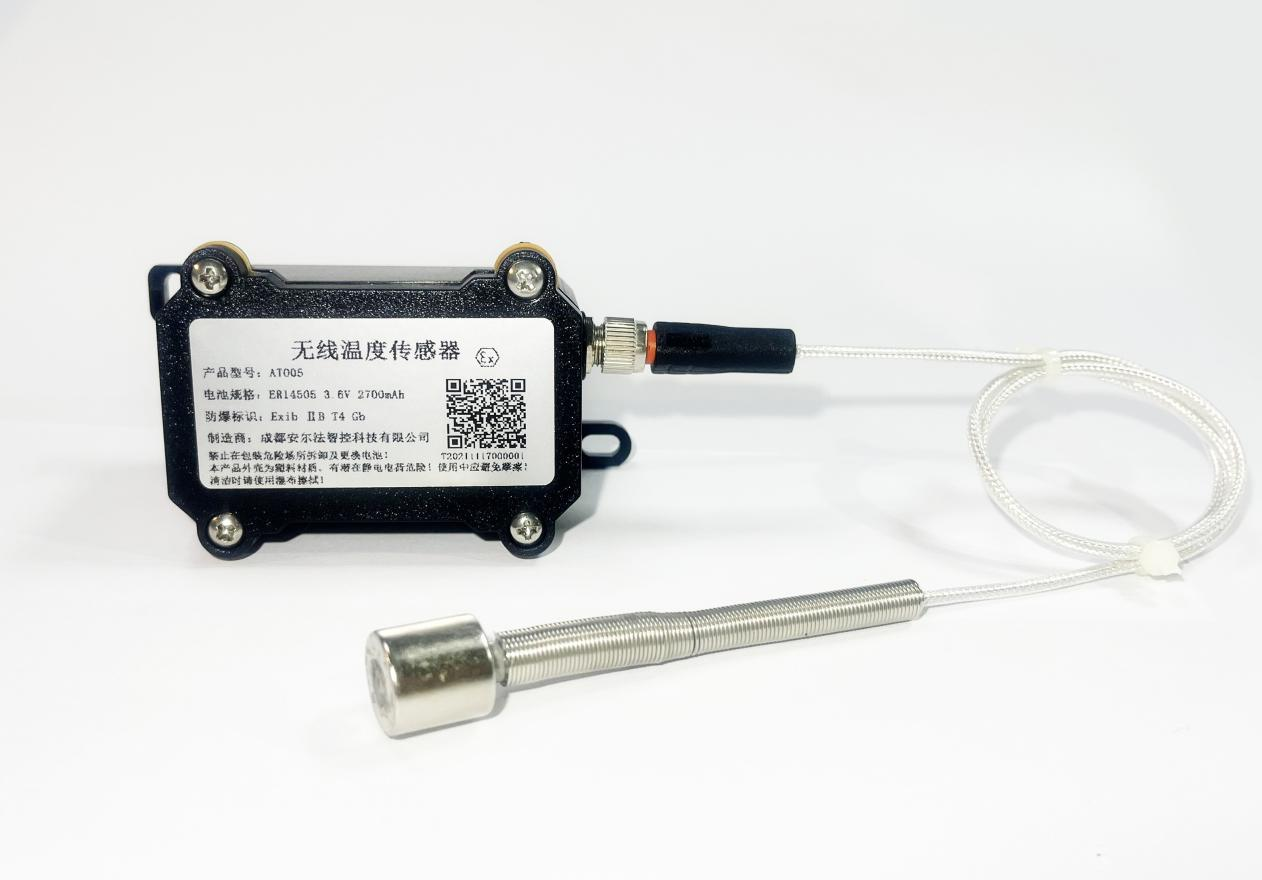

2.3 Structure Overview

The monitoring terminal is composed of a shell, a circuit board, a temperature sensor and an antenna. The plastic shell is made of ABS injection molding and waterproof design to ensure that the equipment works in a closed environment. High protection structure design, easy to install and use, and easy to replace the battery.

The external temperature sensor is connected to the waterproof plug on the shell through the communication line. The communication line is 300mm long. The probe itself is magnetic and can be fixed by magnetic suction.

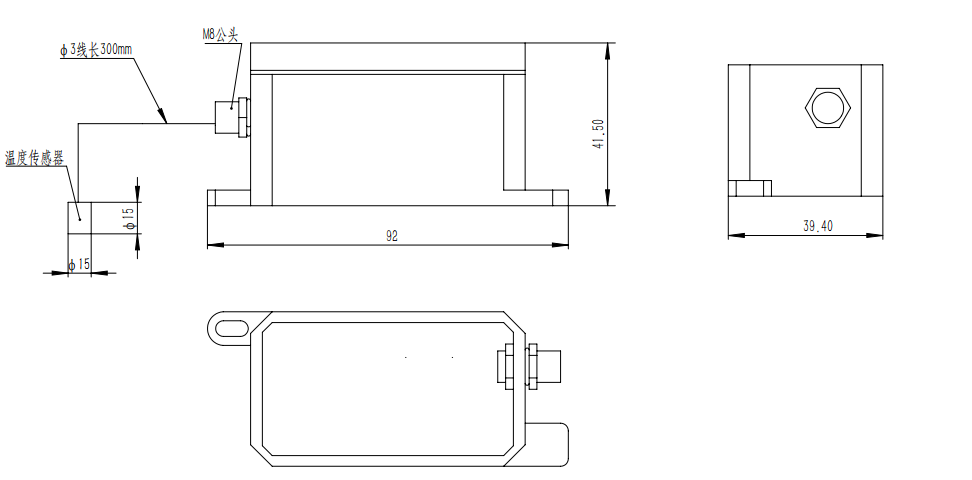

The structural diagram of the sensor is shown in Figure 1 below:

Figure 1

3.Sensor Installation

3.1 Before installation, check whether the parameters listed on the nameplate of the Accelerator&Temperature Sensor conform to the actual use regulations.

3.2 Accelerator&Temperature Sensor shall be installed by professional construction personnel

3.3 Installation sequence

a) Determine the installation position of the equipment.

b)After determining the first step, clean the oil stain at the temperature measuring point and adsorb the sensor probe at the temperature measuring point. (it can be fixed with silicone sealant), as shown in Figure 2 below:

Figure 2

c) Connect the probe and the sensor body.

d) Fix the sensor body in a proper position with screws, as shown in Figure 3 below:

Figure 3

4.Application

4.1Open the cover of the sensor, fix the battery with a tie, plug in the power plug, and the indicator light flashes to indicate successful startup.

4.2Bind the equipment monitoring points in the system and enter the equipment number.

4.2During the use of the monitoring terminal, the terminal battery shall be replaced according to the battery power and signal strength displayed by the system.

4.3The on-site user shall understand the performance of the monitoring terminal. When abnormal operation is found, it shall be inspected under the guidance of our engineer. It is strictly prohibited to open the box cover of the monitoring terminal under the working state of the production line, and it is strictly prohibited to disassemble the equipment for maintenance without authorization.

5.Sensor Maintenance

5.1 Maintenance personnel must attend on-the-job training class to understand the performance of Accelerator&Temperature Sensors and know the requirements for use.

5.2 Regularly clear the shell of Accelerator&Temperature Sensors to improve the heat dissipation performance of Accelerator&Temperature Sensors. Water or cloth wipe are allowed.

5.3 Check the oil stain of the housing, whether it has been impacted by foreign bodies, whether the fixing bolt is loose, if so, it should be strengthened or replaced in time.

5.4 The battery quantity shall be changed in time according to the prompts of the system. It is strictly prohibited to open the equipment for replacement when the production line is working and operate in strict accordance with the instructions when disassembling.

5.5 The Accelerator&Temperature Sensor is explosion-proof and waterproof. The sealing part should not be dismantled or opened frequently, otherwise the explosion-proof performance of the Accelerator&Temperature Sensor will be affected.

6.AJ002 Gateway

Basic info

Purpose: Receive the data transmitted by the wireless Accelerator temperature sensor and transmit it to the server through the network.

Model:AJ002

Explosion-proof mark:

Exd ⅡBT6Gb

Water-proof level:IP66

Working voltage and power

Power:AC220V/50Hz

Up communication

Communication method: Ethernet\4G\WiFi

Down communication

Singal type:Zigbee

Transmission raterate:250Kbps

Working frequency:2.405GHz~2.485Ghz default 2.48Ghz;

Wireless transmit power:22dBm

Wireless communication distance: line-of-sight transmission distance 500 meters @5dbi antenna

Number of sensors connected: no more than 99

X

Welcome to alpha !