78 degree dip angle—How to Implement Comprehensive Mechanized Coal Mining

Alpha Ind. Tech.

3212 (II) Working Face of Lushuidong Coal Mine of Guangneng Company of Sichuan Coal Group is located in the West Wing of Daluowan anticline. The panel length of this coal mine is 550 meters. The length of working face is 110-140 maters. Coal seam dip increases gradually from north to south, which is higher in the south and lower in the north. The average is 60 degrees and the maximum is 78 degrees. There is only one coal seam with an average thickness of 2.5 meters. The large dip angle of coal seam mining is very rare in China and even in the world. Under such conditions, 3212 (II) fully mechanized coal mining face of mining team 1 produced 27985 tons of coal in October, an increase of 12985 tons compared with Guangneng's initial target of not less than 15,000 tons. For two consecutive months, a new high output has been achieved, which marks the initial success of the steep inclined fully mechanized mining project to tackle key problems in Lushuidong Coal Mine.

The Lushuidong Coal Mine was completed and put into operation in December 1981. It has been mining for 37 years. The shape of the coal seam in this mine is like "M". Two anticlines are intersected by one syncline. And the deeper the mining, the greater the dip angle of the coal seam. As mining time goes by, coal reserves of 50° and below become less and less, and an average inclination of 60° and above will become the normal. There is no precedent for China to implement mechanized comprehensive mining at such a large dip. There is no relevant literature as well. Before mining, engineers and technicians do not have full confidence in mechanized mining for such a large dip.

According to the actual situation of coal seams occurrence in the 3212 (II) working face, generally the traditional mining methods use the flexible shield blasting technology for extraction. Since the successful application of the large dip angle fully mechanized mining in 1997, the mine has been using fully mechanized mining. At present, there are very few workers familiar with the flexible shield blasting technology. Moreover, the use of flexible shield blasting technology on the working face with such a large dip angle would not only face the problems of bad mining environment, which harms the health of employees, but also the low production and difficult safety management.

The fully mechanized mining of 3212 (II) working face in Lushuidong Coal Mine has attracted great attention from the leaders of Guangneng Company. They have listened to the report of the mining plan and went to the site several times for investigation and demonstration. Finally, they have agreed to tackle the key problems of fully mechanized mining at 3212 (II) working face. They have joined hands with the machinery and mining experts from Beijing HOT Mining Technology Co., Ltd to gather wisdom to ensure success in solving problems.

There are many technical problems to be solved in installing fully mechanized mining equipment on steep inclined working face with slope of 60°—78°. For example, how to prevent hydraulic support, shearer, scraper conveyor and other equipment from falling and sliding? How to prevent gangue and rib spalling from hurting people? How to prevent the support from stringing and sliding? Many problems remain to be solved one by one.

The gangue board and the airbag designed by Beijing HOT Mining Tech Co., Ltd. have solved the problem that the gangue can hurt people when they enter the machine channel. The problem of people falling down and hurt has been solved increasing the density of the gangue gate between the supports. The difficult problem of the support and conveyor sliding in the working face has been solved by increasing pump pressure and changing production technology. The improved shearer developed by HOT Mining has made the performance of anti-running and braking more than double. By improving the strength of the middle groove 8 word ring, the problem of the middle groove bulgs caused by the breakage of the 8 word ring will be eliminated, the problem which affect the smooth running of the shearer. The improvement of the internal structure of the end support solves the difficulty of pushing the end support and the problem of effectively connecting the roof when the working face is super high. The improvement of the lifting seat of the end support solves the difficulty of the end support lifting. The safety passage of the end support outlet of the working face is designed independently, which solves the safety problem of the exit personnel walking. The problem of easy burning of shearer motor has been solved by adding anti-collision device of shearer motor and increasing safety factor of flexible shaft. The improvement of the lifting seat of the shearer rocker arm solves the problem that the oil cylinder nozzle is easy to be damaged. The shallow hole blasting and retracting technology are implemented in the advanced support of the wind tunnel, which basically solves the problem of large-area empty roof in the corner goaf of the working face.

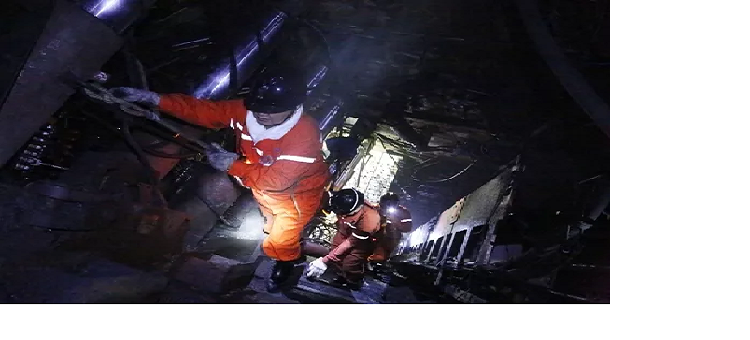

It becomes a serious problem that how to safely install the fully mechanized mining support that each weighs 23 tons on the open-off cut which is dangerous as the cliff.

On the night shift on May 31, the 5th Coal Mining Team began to install the first face end support. The mine director Chen Shengming personally attended the command,but when the support is lowered to 28 meters below the exit, the load-bearing track on the floor was broken, the center of gravity of the support shifted and slipped out of the track.Handling overweight support is a dangerous and difficult task.Cheng shengming command the site people to raise the bracket onto the road on steep slopes where it is difficult for people to stand. However, the same problem occurred again and again in the process of lowering, crushing three places on the track, and the face end support was not put in place until the night shift on June 1.

This installation method is time-consuming, laborious and unsafe, so the mine leaders decided to reinstall the track of 3212 (II) working face and add two more tracks on the original basis, leaving only the upper sleeper for those sleepers that exceeds the height of two sleepers, fully using concrete pouring the lower sleepers together with floor, installation after acceptance.

On August 6, the installation of all equipment in the working face was completed. On August 7, the first equipment debugging of 3212 (II) working face was carried out by the first coal mining team. On August 12, the test mining of 3212 (II) working face opened in the expectation of more than 1700 workers in Lushuidong Coal Mine.

It is the first time to carry out fully mechanized mining operation on such a steep workface. The operators for shear and moving scraper and support were very carefully to prevent improper handling which might lead to slide down and cause accident. But the results of commissioning were beyond everyone’s expectations. The originally worried problem about the support sliding down did not appear. Instead, on August 18, the phenomenon of support shifting up appeared which made 200mm coal seam could not be cut at the side of head. The first mining team adopt lower the support, and after two whole days’ adjustment, the distance between 1# support and face-end support returned to normal finally.

During middle shift of 12 October, the support of working face slid down, and caused the scraper conveyor between 15# and 21# support hunch up. The interval between floor and scraper conveyor reached up to 0.9m, which made the shear could not go down. The site manager reported to superior at once and convened special meeting to discuss how to solve the problem. After 5 days and nights of work, the problem of scraper conveyor hunching up was solved finally.

Ever since commissioning, the team of mine overcame several difficulties of working face completed equipment, such as shifting up and sliding down. During 20 days commissioning in August, more than 8000 tons commercial coal was produced; in September, the team produced commercial coal 26181 tons; in October, the team achieved new peak, and produced commercial coal 27985 tons. During the three months, there was no accident worse than minor injuries. Since then, the fully-mechanized coal mining of 3212(II) steep working face stepped towards normal.