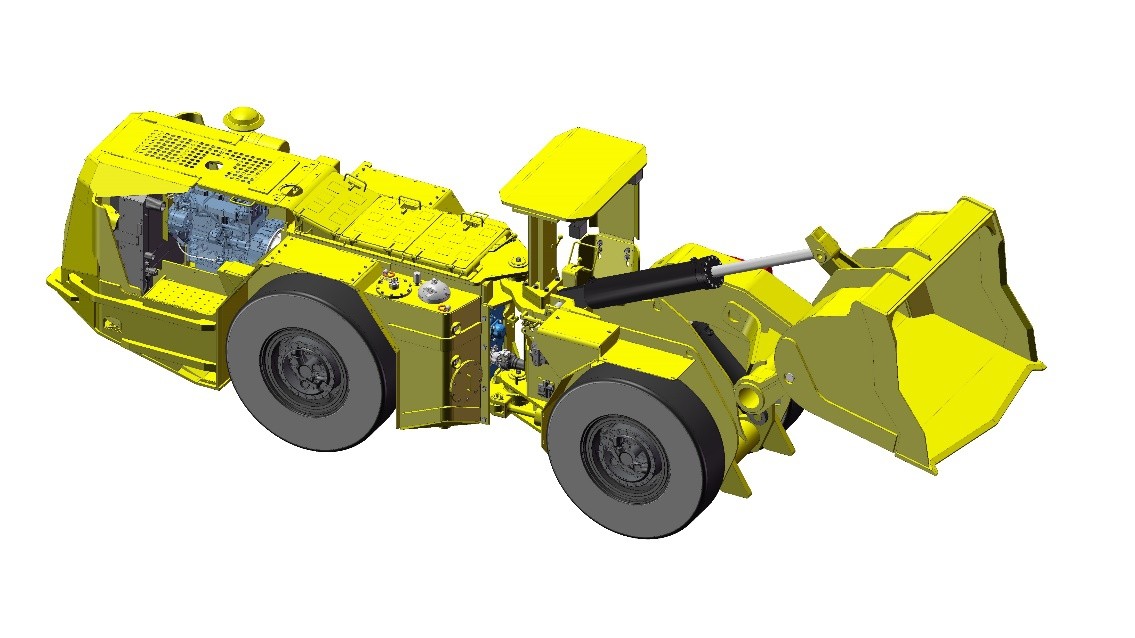

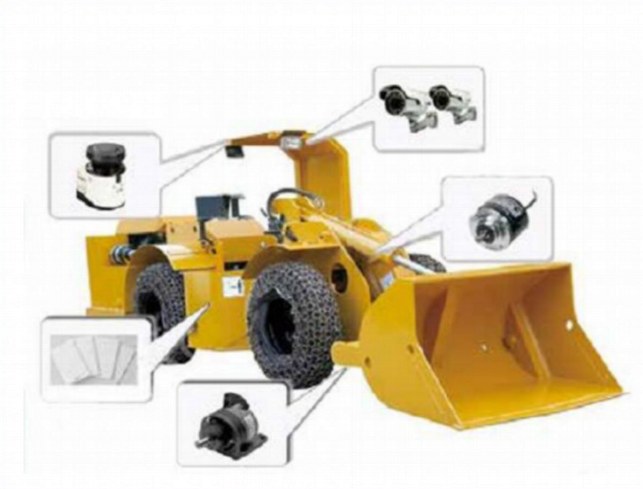

What should Intelligent underground LHD have? ALPHA TLHD-WJ-2D Diesel LHD

Alpha Ind. Tech.

ALPHA is always focus on underground mining safety and efficiency.And we have exported our LHD to different countries. And now, ALPHA is also manufacturing our Brand new model intelligent LHD.

No alt text provided for this image

This ALPHA TLHD-WJ-2D Diesel LHD adopts the most advanced manufacturing standards, which refer to Epiroc's LHD. At the same time, it has two operation modes of vehicle local control and remote control, which are flexible and optional to ensure the operation safety of dangerous areas. And through the built-in sensor, the operation status data of the LHD is uploaded to the Alpha Cloud Intelligent Maintenance to do data fault diagnosis and achieve predictive maintenance of the LHD.

The LHD is being assembled at the Techgart Tianjin factory(Techgart is shareholder of Alpha) and it is expected to launch the complete equipment in July.

No alt text provided for this image

What ALPHA LHD has?

1. The power mechanism adopts the pure imported Deutz Diesel engine, which has strong power and reliable performance;

2. The special bucket with full machine automatic welding process is made of NM500 wear-resistant steel at the easily worn part, extending the service life.

Underground LHD bucket, ALPHA LHD, ALPHA undergound loader, ALPHA Scooptram bucket

3. With electric control handle, electronic instrument, LCD display, it has very high operability.

No alt text provided for this image

4. The gearbox has four gears for forward and backward, which can efficiently adjust the power, etc.

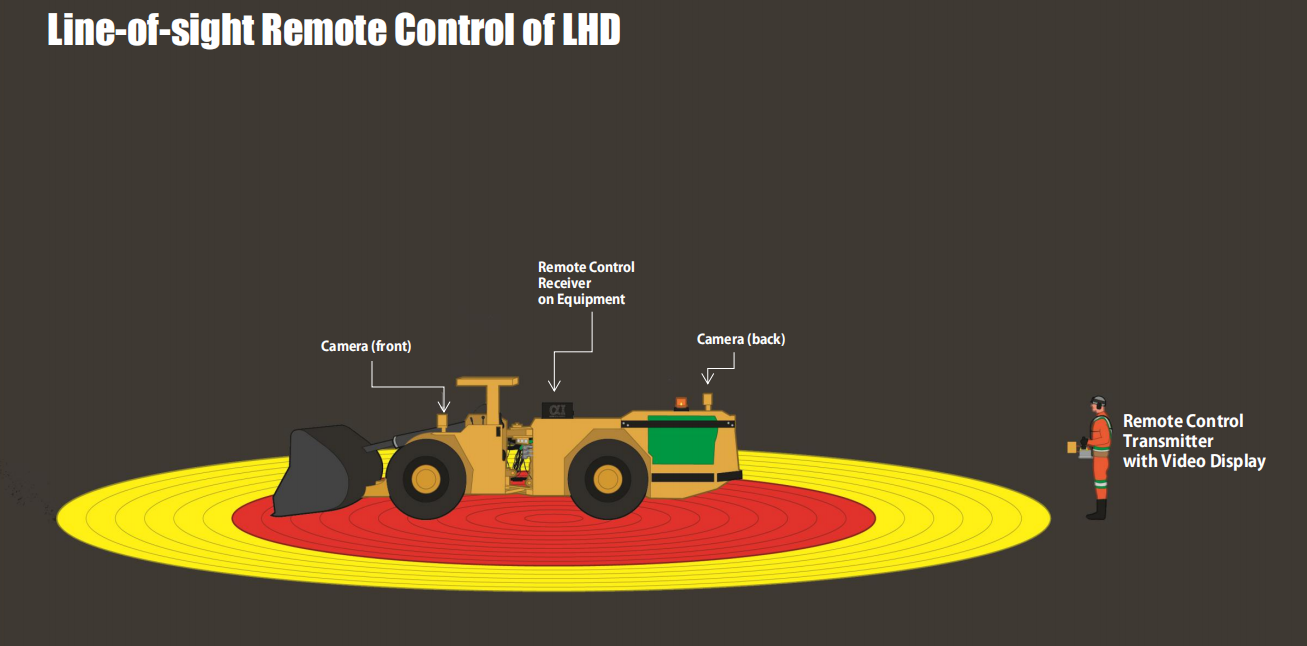

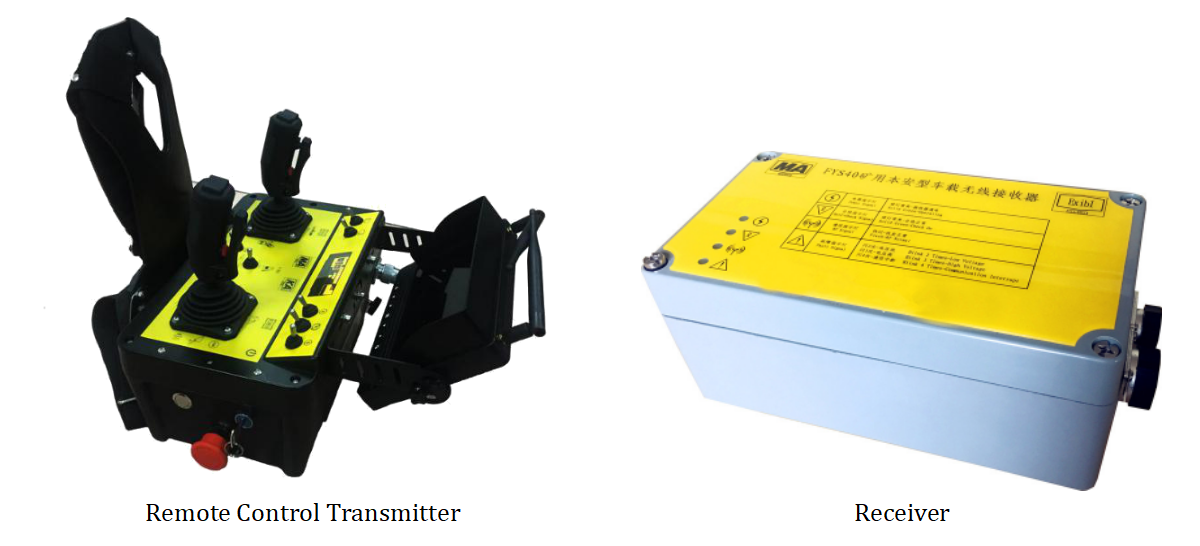

Intelligent Remote Control Sytsem

ALPNA is professional at wireless remote control system. So TLHD-WJ-2D LHD has two operation modes of vehicle local control and remote control, which are flexible and optional to ensure the operation safety of dangerous areas.

LHD remote control, Underground Loader Remote Contrrol System, Atlas LHD, Expirco LHD

Operator use the Remote Control transmitter to operate LHD in a distance no more than 100 meters, which can realize stable point-to-point connection between remote control transmitter and receiver in the LHD.

No alt text provided for this image

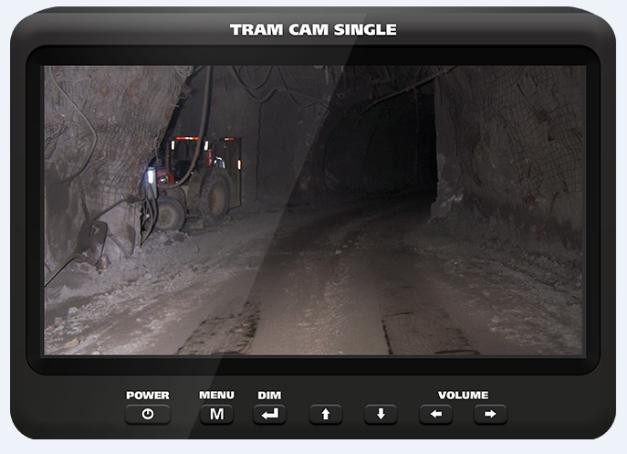

The operator mainly use the video play in the transmitter to oberserve the LHD working environment.

No alt text provided for this image

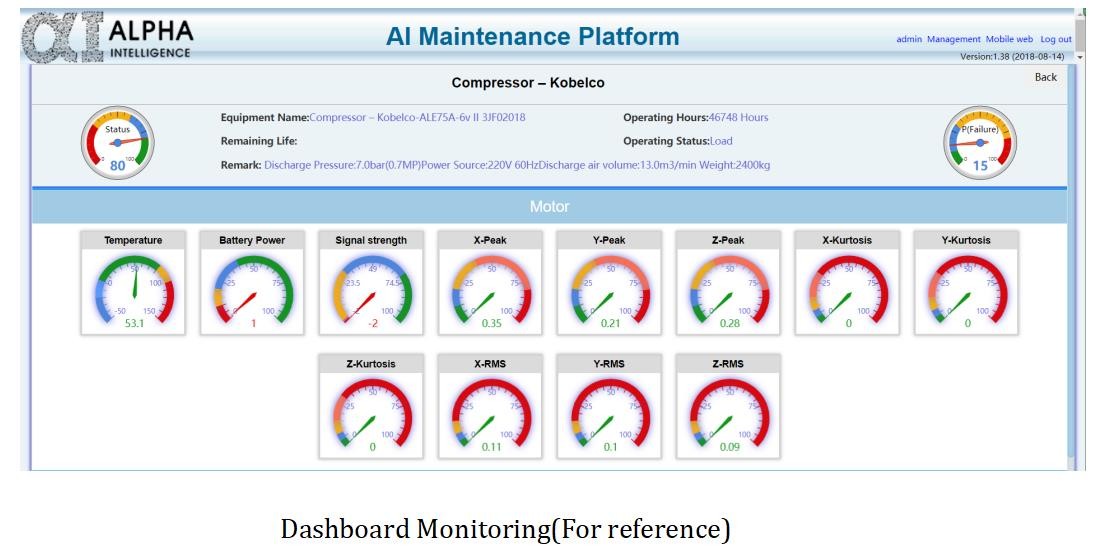

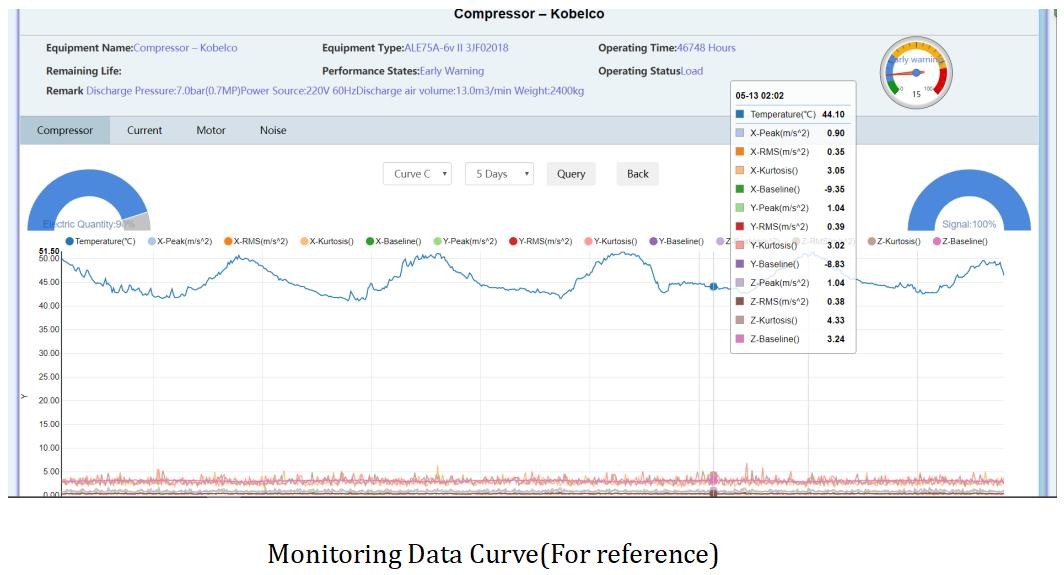

LHD IoT Condition Monitoring(PdM)

ALPHA is also good at data analysis and intelligent algorithm, use our Cloud Platform to realize the predictive maintenance of single equipment.

No alt text provided for this image

Various sensors will be installed on the equipment to monitor the running status in real time. LCD screen on the remote transmitter can display the signal and feedback with error alerts as well.

Engine parameters: Oil pressure, engine temperature, engine speed, etc.

No alt text provided for this image

Hydraulic parameters: Hydraulic oil pressure, brake pressure, hydraulic oil tank

Others: Fuel tank level, travel time, engine operating status, braking state, neutral state, etc.

No alt text provided for this image

All the sensors' data are transmitted to LHD VOBC via CAN BUS, and the VOBC is connected to LTE moudule which upload all the data to ALPHA Clould Platform. Then the Cloud store the data and through the intelligent algorithm to analyze the data, and carry out the LHD fault diagnosis, to achieve predictive maintenance.

No alt text provided for this image

In the future, ALPHA will know every ALPHA LHD's working status and help our client to get better after-sales service.

To get more info about our different LHD model and PdM system, just contact us:

Email: kyle.lee@alpha-technology.com.au

Tel/Whatsapp(Skype): +86 15756875803

Web: www.alpha-technology.com.au